2014 Space Odyssey: NASA Puts Finishing Touches on 3D-Printed Telescopic Camera

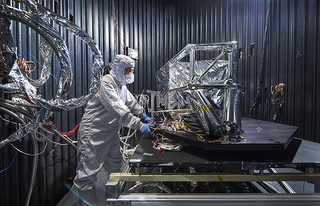

September can’t come soon enough for NASA engineers who will unveil a state-of-the-art 3D-printed imagining telescope that will serve as a space camera. Currently, the project is being led by engineer Jason Budinoff.According to a press release on NASA’s website, “Under his multi-pronged project, funded by Goddard’s Internal Research and Development (IRAD) program, Budinoff is building a fully functional, 50-millimeter (2-inch) camera whose outer tube, baffles and optical mounts are all printed as a single structure. […] The instrument will be equipped with conventionally fabricated mirrors and glass lenses and will undergo vibration and thermal-vacuum testing next year.”

The telescopic camera is manufactured using a computer programmed laser that melts down metal parts. Like most 3D print jobs, the product is put together layer by layer – each section building on the next like a virtual stack of poker chips.

Fox News notes, “Both instruments are being built to demonstrate how 3D printing (also called “additive manufacturing”) can be used as a boon for space exploration. The new technique could cut down both the time and cost of traditional manufacturing.”

In addition to conceiving and creating the prototype, engineers must now ensure the 3D model is fit for space conditions. Budinoff is confident that the technology will stand the test.

In NASA’s press release, Budinoff stated: “When we build telescopes for science instruments, it usually involves hundreds of pieces. These components are complex and very expensive to build. But with 3-D printing, we can reduce the overall number of parts and make them with nearly arbitrary geometries. We’re not limited by traditional mill- and lathe-fabrication operations.”

This is not the first 3D-printed tool NASA will manufacture. So far the organization has used the technology to build rocket engine parts, as well as what one might call a “universal” pizza maker meant to produce space pies.